Why did Culture Shrimps in Nursery Systems?

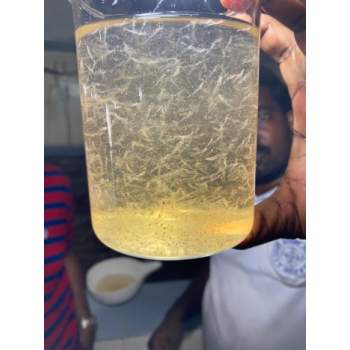

- Nursery systems for vannamei culture across the world are reaching new heights with high density stocking and very intensive farming systems with zero water exchange in order to keep all parameters constant. Prerequisites are highly efficient filtration systems similar to those used in hatcheries.

- Shrimp juveniles reared through nurseries before stocking into growout ponds are healthier and stronger, grow faster and typically have better FCR and survival rates, as well as significant potential for compensatory growth.

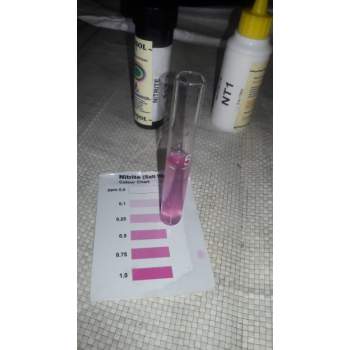

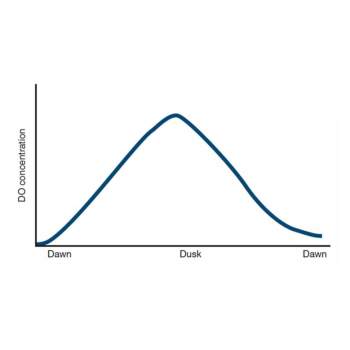

- In a nursery system there is better control of water quality and shrimp health.

- Shrimp nursery systems are valuable production tools and a significant opportunity for the shrimp farming industry to increase efficiency and profits, and in some cases to help manage some diseases.

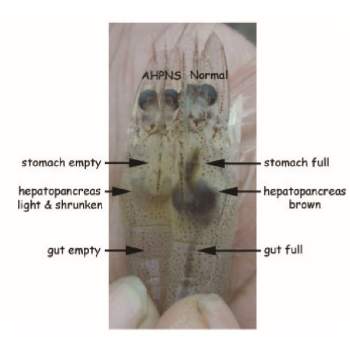

- In the nursery system, the animals could be monitored better as it was a smaller area of operation. It could check the occurrence of disease right to start when the infection sets in. If he nursery animals are found to be infected by diseases, the stock could be discarded and a fresh batch could be quickly started, without jeopardizing the entire farm. This way the entire farm will not have to be cleared and disinfected. It saved a lot of time and energy and is economically a better option.

- In all, managing one nursery area for about a month is a lot more economical than managing the same stock spread out over a huge area.

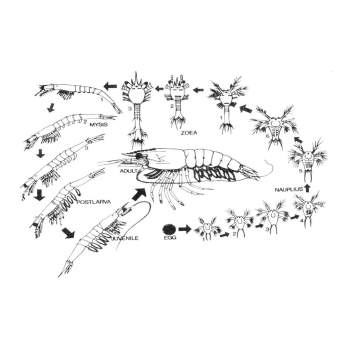

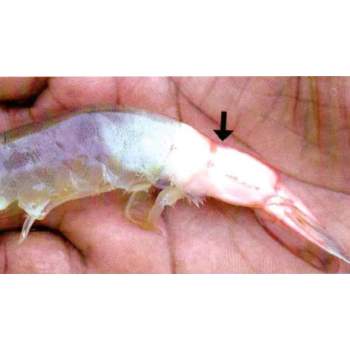

- Properly designed and implemented, they are high-biosecurity facilities to grow post larvae (PL) at high densities, from about 2 mg to sizes as large as 3 grams, resulting in healthy, strong and uniform juveniles with significant potential for compensatory growth after their transfer for final grow-out to market size.

- In general, nurseries typically use plastic-lined tanks or raceways covered by plastic greenhouses or roofs suspended by cables, with an area of 300-7500 m2. Systems can be square or round (typically with circular flow around a central drain) or rectangular (with continuous, rotating water current around a central baffle). Stocking densities range from 500 to 10,000 PL/m3, with individual sizes of 0.3-3g at harvest, and harvest biomasses of 1-3 kg/m3.

- Stocking post larvae (PL) after the nursery phase (usually up to PL45) instead of PF 10-12 direct from hatcheries can reduce the duration in grow-out ponds by 20-25 days and improve feed conversion ration by 10-20%. This is now one of the strategies to mitigate EHP (and EMS in affected Countries), by stocking larger size PL into grow-out ponds. Two biggest costs in shrimp farming are feed and duration of culture so introduction of the nursery phase helps to reduce risk and improve profitability.