Acute hepatopancreatic necrosis disease (AHPND) earlier known as early mortality syndrome (EMS) or acute hepatopancreatic necrosis syndrome (AHPNS) has been causing significant losses in shrimp farms in China, Vietnam, Malaysia, and Thailand since 2009. The disease affects both black tiger shrimp and Pacific white shrimp and is characterized by mass mortalities during the first 20-30 days of stocking.

Research by the University of Arizona has identified that the disease is caused by the bacterial agent Vibrio parahaemolyticus, which is transmitted orally and colonizes the shrimp’s gastrointestinal tract. This then produces a toxin that causes tissue destruction and dysfunction of the shrimp digestive organ known as the hepatopancreas.

Causes

The disease is caused by a unique strain of Vibrio parahaemolyticus, which can produce toxins responsible for the primary pathology in affected shrimp. Other non-Parahaemolyticus strains such as V. campbellii, V. harveyi, V. owensii, and V. punensis are also found to contain the same toxic genes and may also cause the disease.

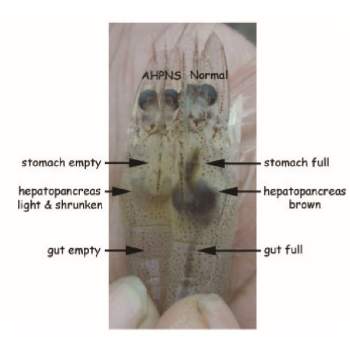

Symptoms

Management