Litopenaeus vannamei is a decapod crustacean which is native to the Eastern Pacific coast from Sonora, Mexico in the North, through Central and South America as far South as Tumbes in Peru, in areas where water temperatures are normally >20°C throughout the year. Penaeus vannamei live in tropical marine habitats. It has been introduced widely around the world since the 1970s, but especially since 2000, as it has become the principle cultured shrimp species in Asia.

Litopenaeus vannamei (Boone, 1931)

Common name: Whiteleg shrimp

Colour: Coloration normally translucent white, but can change depending on substratum, feed and water turbidity.

Species identification: It has 7-10 teeth on the dorsal rostrum and 2-4 on the ventral side.

Taxonomy:

Order: Decapoda

Suborder: Natantia

Infraorder: Penaeidea

Superfamily: Penaeoidea

Family: Penaeidae

Genus: Penaeus

Species: P. vannamei

Habitat: Depth 0 to 72 m. Bottom mud. Marine (adults) and estuarine (juveniles)

Size: Maximum size 23 cm, with maximum Carapace Length of 9 cm. Maximum weight of female 120 g. Females commonly faster growing and larger than males.

Biology: Males become mature from 20 g and females from 28 g onwards at the age of 6–7 months. P. vannamei weighing 30–45 g will spawn 1,00,000–2,50,000 eggs of approximately 0.22 mm in diameter. Hatching occurs about 16 hours after spawning and fertilization. The first stage larvae, termed nauplii, swim intermittently and are positively phototactic. Nauplii do not feed, but live on their yolk reserves. The next larval stages (protozoea, mysis and early postlarvae respectively) remain planktonic for some time, eat phytoplankton and zooplankton, and are carried towards the shore by tidal currents. The postlarvae (PL) change their planktonic habit about 5 days after moulting into PL, move inshore and begin feeding on benthic detritus, worms, bivalves and crustaceans.

Rain presents a significant challenge for shrimp farmers all over the world. Rainfall can quickly alter pond conditions and trigger a chain of events that could result in sub-optimal water quality and stunted shrimp growth. Rain generally has a temperature of 5 to 6 degrees-C lower than the environment, but it can be much lower if it is associated with massive low-pressure systems. Shrimp is a cold-blooded (or poikilothermic) species. Its body temperature can only change in a limited range. But, if environmental factors change dramatically and exceed permitted limits, shrimp will be weak, shocked, and possibly dead.

When it rains, temperature, salinity, pH and dissolved oxygen in ponds will be reduced significantly. Thus, shrimp care during rainy season with continuous and prolonged rains becomes difficult for people, even with experienced farmers. As a result of the dissolution of carbon dioxide (CO2), rain is actually a weak solution of carbonic acid with a pH of 6.2 to 6.4. These two physical factors tend to lower the temperature and pH of the shrimp ponds. Additionally, as a consequence of dilution, salinity and hardness also decrease due to the reduction in ion concentrations in solution.

Effect of rainfall on water quality parameters

|

Parameter |

Rainfall effects |

|

Temperature |

Generally decreases by 3-5°C |

|

pH |

Initially drops to 6.7 and more afterwards |

|

Salinity |

Decreases depending on volume |

|

Hardness |

Decreases depending on volume |

|

Turbidity |

Increases due to clay particles |

|

Dissolved Oxygen |

First increases, then decreases markedly |

|

H2S and Ammonia |

Can increase after 2 to 3 days |

Practices to minimize the impact of heavy rains:

Before the rains:

During the rains:

After the rains:

Farming protocols for the rainy season:

Bacterial infections of farmed shrimp are quite common and likely the major cause of mortality in farmed shrimp. Vibriosis is one of the most severe bacterial diseases in shrimp farming caused by Vibrio spp. These bacteria from part of the natural microbiota of wild and cultured shrimp and the marine environments. Vibrio infections have become a major constraint of the production and trade in shrimp aquaculture. They are responsible for several diseases and mortalities of up to 100% and cause crop loses globally.

Vibrio usually associated with multiple etiological agents. Vibrio has been reported in penaeid shrimp culture systems implicating at least 14 species and they are Vibrio harveyi, V. splendidus, V. parahaemolyticus,V. alginolyticus, V. anguillarum, V. vulnificus, V. campbelli, V. fischeri, V.damsella, V. pelagicus, V. orientalis, V. ordalii, V. mediterrani, V. logei etc. However some Vibrio species have been identified as primary pathogen, including V. parahaemolyticus and V. harveyi have been described as the main pathogenic species in shrimp.

Clinical signs of Vibriosis

Shrimp diseases associated with Vibriosis

Vibrio can remain in the environment without causing disease, but can very easily switch from opportunistic and commensal to pathogenic when conditions change. Thus, its ability to cause disease or increase in virulence, is a complex process affected by many variables, including host, vibrio species, developmental stage, physiological conditions, environmental stress, and infection method.

They are several diseases associated with Vibriosis.

Diagnosis

Diagnosis of vibrio infection is based on clinical signs and the histological demonstration of rod-shaped Vibrio bacteria in lesions, nodules or haemolymph. Excised organs and haemolymph may be streaked on a Vibrio-selective (TCBS) or general marine agar plate. Vibrio isolates may be identified by a number of methods, including: Gram stain, motility, an oxidase test, mode of glucose utilisation, growth in the presence of NaCl, nitrate reduction and luminescence.

Vibrio threshold in shrimp farms:

There are many vibrios maximum threshold standards in farms. Most of them are for Vibrio spp. in pond water. These are the common maximum thresholds used by shrimp farms:

How to prevent Vibrio problems?

Vibrios are difficult to eradicate because they adopt well to different environment conditions and can adopt state when facing adverse conditions. However, Vibriosis is controlled by rigorous water management and sanitation to prevent the entry of vibrios in the culture water and to reduce stress on the shrimps. Pond Management and robust gut health are important strategies to control vibrio, together with frequent sampling to monitor their levels in the shrimp gut and pond ecosystem.

Good site selection, pond design and pond preparation are also important. Maintain adequate water quality with low bacterial biomass, A stable phytoplankton bloom and a proper feeding program, Sterilize or filter recirculated water, Routinely monitor shrimp and pond for early diagnosis of a problem, Avoid temperature extremes or rapid variation in temperature, handling, overcrowding, and other stressors, Infections opportunistic and probably result from poor husbandry; may be secondary to other disease processes. An increase in daily water exchanges and a reduction in pond biomass by partial harvesting are recommended to reduce mortalities caused by vibriosis.

The combination of gut acidifiers, prebiotics, use of natural antimicrobials and Probiotics, Bacteriophage applications, immunostimulants and non-antibiotic substances has superior specificity against vibriosis and Luminescent Bacteria (LB) coupled with Best Aquaculture Practices (BAP) , which makes it an effective management tool for the control of vibriosis and bacterial toxicity in aquaculture.

Treatment

Use V Phages Growout immediately when various symptoms of Vibriosis as Luminescence in water, infections in shrimp and or low feed intake etc., correlated by lab test.

Ammonia is the major toxic component produced continuously by shrimps during culture. It can also accumulate in the water due to the decomposition of organic matter as excess feed, faeces, dead shrimp and dead algae. Ammonia is the main end product of protein catabolism in crustaceans and can account for 60–70% of nitrogen excretion with only small amounts of amino acids, urea and uric acid. Of the nitrogenous compounds, ammonia is the most toxic with nitrite and nitrate being less toxic to shrimp.

Ammonia is the primary excretion product of protein metabolism. In water, ammonia is present in both ionized (NH4+) and un-ionized (NH3) state, with NH3 as the toxic form due to its ability to diffuse across cell membranes. Unionized ammonia is highly toxic to the shrimp and must be removed from the system. The relative proportions of NH3 and NH4+ depend on pH, temperature and to a lesser extent on salinity. Ammonia is nitrogenous waste produced from feed input and microbial decomposition of organic matter in water columns. Shrimp feed is usually high in nitrogen.

In vannamei culture, sometimes only 22 percent of the Nitrogen input is converted to harvested shrimp. 57 percent is discharged into the environment and 14 percent remains in the sediment.

Ammonia Toxicity in Vannamei

Ways to prevent ammonia build-up

If you want to solve the problem of Ammonia, you should do the following:

White feces disease is one of the most serious problems in shrimp culture. It causes lower productivity in shrimp farming. WFD becomes apparent when the digestive system of shrimp malfunctions and feces turns from normal brownish color to pale white color. WFD has caused significant economic losses to shrimp farmers, because of high FCR, slow growth, and variable sizes of shrimp at harvest. White feces syndrome usually occurs after 60 days of culture (DOC) and it may be accompanied by high shrimp mortality. The disease can cause moderate to severe economic loss by reducing shrimp survival by 20–30 percent.

Causes

Poor water quality, unhealthy seed, high vibrio loads, Enterocytozoon hepatopenaei (EHP), and the Presence of Protozoa gregarines-like organisms in the intestine and hepatopancreas are some of the reasons for causes of the disease.

Symptoms

Remedies

Cause of white faeces syndrome and treatment is uncertain. However reduced stocking density, proper water exchange together with better management practices will be helpful in evading White Fecal Disease.

Using of V Phages Growout immediately on observation of few strands on white fecal matter floating on water, or on check tray. Start this treatment to recover shrimps.

EHP or Enterocytozoon Hepatopenaei is an yeast-like fungus belonging to a group called “microsporidia”, which are obligate intracellular parasites. It was first reported as an unnamed microsporidian from growth retarded black tiger shrimp Penaeus monodon from Thailand in 2004. This fungus infects the hepatopancreas of the shrimps, so it’s called as Hepatopancreatic microsporidiosis (HPM). It also has smaller spores (approximately 1 μm in length) and is currently known to infect both P. monodon and P. vannamei.

CAUSES

SYMPTOMS

DIAGNOSTIC MEASURES

PREVENTION

Regular health assessments are recommended. If there is a large difference in the size of PL, if PL feeding activity is less than expected, the number of lipids in the hp drops, growth and moulting slows, then these are also good indications of infection. The number of swollen tubules may provide an indication of how advanced infections are.

Some important insights on practical solutions for managing EHP is described below:

HATCHERY

NURSERY

GROWOUT

Biosecurity in shrimp farming can be defined as the preventive measures for the exclusion of specific pathogens from cultured shrimps. Nowadays, Disease outbreaks in shrimp culture is considered as the highest level of threat. Based on the previous history of the last few years since the development of shrimp culture, mass disease outbreak has caused havoc throughout the shrimp producing regions. Apart from ensuring Pathogen-free status as SPF seeds, farmers should give equal attention to horizontal transmission of diseases from pond to pond, farm to farm, and village to village.

This is done by following precautionary measures, through proper coordination among farmer’s associations regarding judicious use of water resources, seed stocking density, periodic treatment and disposal of sludge, drainage after harvest, closure, and disposal of crops due to viral diseases, etc.

The following biosecurity measures to be followed in shrimp farming:

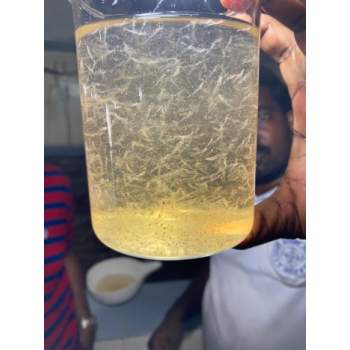

Shrimp health management has become the main focus of improving production and minimizing infectious diseases in shrimp ponds for the smooth development of the aquaculture industry. To accomplish this goal, we should be concerned with the quality of post larvae especially the selection of high-health post larvae shrimp, before stocking in the pond.

Post Larvae selection is important as it will determine the performance and production of the ponds. The objective of larvae selection is to obtain the best survival and growth in the pond. There are several characteristics of good quality post larvae, and visual observation can be used in identifying good quality or healthy post-larvae for stocking.

Some of the useful criteria are given below to help farmers identify high-health post larvae:

1. Activity:

2. Size:

3. Disease-free:

a) Check of larvae are red/pink in color - Caused by expansion of Chromophores,it indicates

b) Any chronic or acute mortality - Indicative of advanced disease stress

c) Any limb or appendage necrosis - Indicative of bacteria infection

d) Check of fouling organism, e.g Zoothamnium - Indicative of poor water quality Overfeeding

e) Check Hepatopancreas -

Brownish – normal

Whitish – disease problem

f) WSSV should be negative - Accepted with PCR

4. Gut:

5. Molting:

6. Pigmentation:

(a) Shape

(b) Color

7. Muscle development:

The ratio of width of gut and body depth below the gut at the 6thsegment,

healthy PL should be 1:4 or > 4

8. Antibiotic usage:

9. Stress test:

10. External features:

For a healthy PL, the antennal scales of head portion are closed together whereas the tail fan (uropod) is widely opened. Closed uropods are indicative of young fry not yet suitable for stocking (

11. Feeding activity:

The pH will vary in the pond environment depending on a number of factors

Effect of pH in Shrimp Culture:

Water Quality is vital for a successful crop. Availability of good quality water is required quantities is one of the most important prerequisites for sustainable aquaculture. While locating the farm site, careful study should be made on the source of water, a quantity of water available during the different seasons, and the quality of water. All instructions and precautions should be followed strictly to get the best out of your farm.

Some Key Points to follow are,

Optimum water quality parameters for Vannamei

Maintenance of water quality within the optimal levels during the culture is very essential for ensuring good growth and survival of shrimps are presented below.

|

Water Parameters |

Optimal Range |

|

Dissolved Oxygen |

>5 ppm |

|

Temperature |

28-310C |

|

pH |

7.5 – 8.5 |

|

Transparency (Secchi disc) |

35 – 45 cm |

|

Salinity |

10-25 ppt |

|

Total Alkalinity as CaCO3 |

100-160 ppm |

|

Total Hardness as CaCO3 |

>2000 ppm |

|

Calcium/Magnesium Ions Ratio |

1:3 |

|

Total Ammonia (NH4+) |

< 1.0 ppm |

|

Unionized Ammonia (NH3) |

< 0.1 ppm |

|

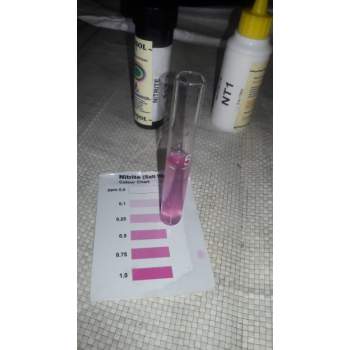

Nitrite |

< 0.2 ppm |

|

Hydrogen Sulphide (H2S) |

< 0.1 ppm |

Lithopenaeus vannamei is highly susceptible to a number of viral pathogens. Certain viral pathogens of shrimp, notably White Spot Syndrome Virus (WSSV) and Infectious Hypodermal and Hematopoietic Necrosis Virus (IHHNV), are transmitted from broodstock to postlarvae that are then stocked with the infection, increasing the likelihood of a serious profit-limiting disease outbreak. In order to eliminate the presence, the virus in the seed, Specific Pathogen Free (SPF) stock has been developed by producing a number of generations in highly biosecure facility with continued surveillance of pathogen presence.

SPF status refers to the absence of specific pathogens from a population of shrimp. SPF shrimp are selected through a multigenerational process that includes strict quarantine and endless sampling – typically polymerase chain reaction and histopathology – for the presence of the pathogens of concern. The primary advantage to using SPF animals relates to the ability to control disease. One can expect to see other advantages over years to come, including real disease resistance, enhanced growth and stress resistance.

The specific pathogen free (SPF) Litopenaeus Vannamei has capacity to produce quality seeds with faster growth and higher survival rates for commercial farm. The status of SPF signify that the shrimps have passed through a rigorous quarantine and disease screening process that determined them to be free from specified pathogens of concern to culturists. They are repeatedly bred under controlled conditions to maintain their freedom from specific pathogens and the SPF designation itself is tested on a regular basis. Offspring of SPF shrimp are not considered SPF unless they are produced and maintained at an SPF facility.

Many farmers have been led to believe that SPF animals can solve all of their problems. For farmers thoroughly disenchanted with the problems associated with trying to rear non-SPF P. vannamei, the success they enjoy by the shift to SPF P. vannamei has been nothing short of miraculous. However, this does not mean they can become complacent and ignore basic biosecurity rules.